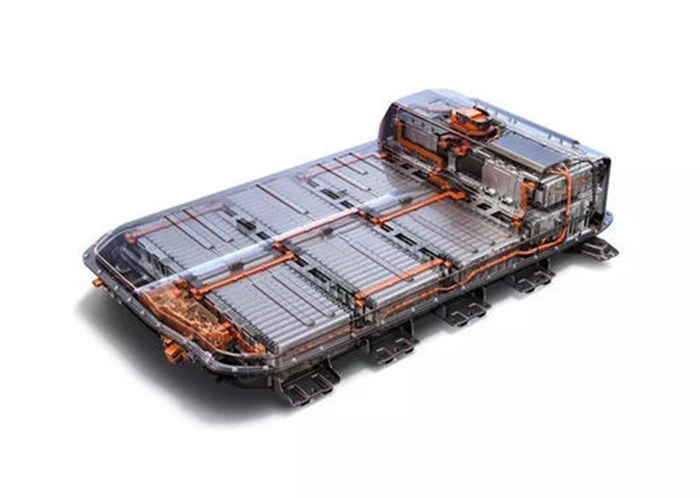

The battery pack is the core energy source of the EV and provides driving power for the EV. It mainly forms the main body of the battery pack through the case envelope.

The battery pack composition mainly includes battery cells, modules, electrical systems, thermal management systems, cases and BMS.

As the carrier of the battery module, the EV battery pack case plays a key role in the safe operation and protection of the battery module. Its appearance design is mainly carried out from the aspects of material, surface anti-corrosion, insulation treatment, product identification, etc.

The EV battery pack case must meet the strength and rigidity requirements and the electrical equipment shell protection level IP67 design requirements and provide collision protection. The battery module in the box is rooted on the bottom plate, and the wiring harness is reasonable, beautiful and reliable.

1. It is easy to maintain.

2. In the event of a car collision or spontaneous combustion of the battery pack, it is advisable to consider the structure or protective measures to prevent fireworks, liquids, gases, etc. from entering the compartment.

3. The battery pack case should be left with the nameplate and safety sign layout, leaving enough space and fixed foundation for the installation of insurance, power line, collection line, and various sensing elements.

4. All non-polar basic insulated connectors, terminals, and electrical contacts should be protected. After the connectors, terminals, and electrical contacts are joined, they shall meet the requirements of protection level.

1. The outer surface has no obvious defects such as scratches and deformation, and the surface coating is uniform.

2. The parts are fastened reliably, without rust, burrs, cracks and other defects and damages.

1. Vibration resistance and impact resistance. After the test, there should be no mechanical damage, deformation and loosening of the fastening parts, and the locking device should not be damaged.

2. Adopt the power battery box fixed by the locking device, the locking device should be reliable and have measures to prevent misoperation.

1. After the test, the protection level of the lithium-ion battery pack casing is not less than IP55.

2. Personnel protection against electric shock shall meet relevant requirements.

After completing the design of the entire power battery system, the manufactured power battery system must undergo a bench performance test to verify whether it meets the design requirements, and after the installation test, the system is improved and perfected.

As an advanced welding process, the lithium-ion battery laser welding machine is widely used in the manufacturing process of EV batteries, including the welding of battery pack cases.

Contact: WinAck

Phone: 0086- 188 0506 7911

Tel: 0086- 592 - 7297239

Email: timi@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China