The consistency of lithium battery cells refers to the convergence of a group of important characteristic parameters of cells, and is a relative concept. For multiple cells in the same battery pack, each parameter is preferably within a relatively small range, which is good for consistency.

With the addition of the time dimension, consistency refers to the consistency of all characteristic parameters in the entire life cycle of all cells in the battery pack. Increasing inconsistency considering capacity attenuation, inconsistent internal resistance growth, and inconsistent aging rate are added. The life of the entire battery pack is our ultimate goal of paying attention to consistency.

Pursuing the goal of consistency, in addition to exerting the maximum capacity of the battery pack (including maximum power, maximum current, and maximum available capacity) in the current state, it also wants such capacity to be maintained for as long as possible.

Consistency is the consistency of all cells within the battery pack, regardless of the serial or parallel relationship. The following is not a comprehensive discussion, just an example.

Parallel connection

The cell with low discharge capacity (code B) is connected in parallel with other normal cells to become a parallel module D. For example, this is a module with 10 batteries connected in parallel. The system discharges, and each parallel module needs to provide the same current, such as 100A. For other normal parallel modules, each battery discharges 10A; B can only discharge a maximum of 1A current, then the other 9 batteries each need to discharge 11A. Under normal circumstances, the long-term overload, compared with other parallel modules, the aging rate of these cells is faster. One day, the overall maximum discharge capacity of this parallel module cannot reach the designed maximum capacity. This parallel battery pack becomes the bottleneck of the discharge capacity of the entire battery pack.

Series connection

A battery pack D with a deeper aging degree than other battery packs appears in the entire battery pack. The capacity of D is small, and the internal resistance is large. In response to the curve of the SOC and the open circuit voltage, the open circuit voltage corresponding to the same SOC, the D terminal voltage is too high. The entire battery pack is charged, D reaches the charging cut-off voltage first, and the battery pack stops charging.

Therefore, the unit consistency is not a matter of a certain module welded together, but the requirement for all battery cells in the same battery pack.

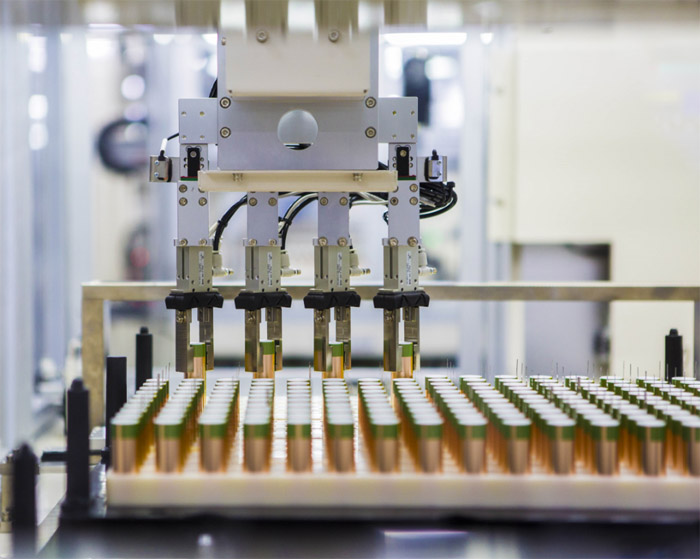

In summary, in order to ensure the high consistency of the battery cells, the sorting of lithium battery cells is very important. Usually, battery capacity testing equipment is used to sort the battery capacity, and then the cells with the same capacity are used to sort the battery voltage and internal resistance with automatic battery sorting equipment. At present, this is the work that battery pack assembly factories must do to ensure product quality.

Contact: WinAck

Phone: 0086- 188 0506 7911

Tel: 0086- 592 - 7297239

Email: timi@winack.com

Add: WinAck Group, Xiangbei Industrial Zone, Xiamen City, China